Quality management concept

1. The quality management system throughout the whole life cycle of the drug is built, to ensure the quality attributes in the process of research and development design, production, circulation sales, the use for patients until delisting.

2. Quality by design (QBD): The quality assurance system extends to the whole process of new drug research and development, to ensure the standardized operation of drugs from the development, test, technology transfer, clinical operation to various stages, and ensure safety and effectiveness of drugs from the source.

3. Total quality management (TQM): Taking the product quality as the core, and all staff participation as the basis, the choice of suppliers, raw materials procurement, traditional Chinese medicine materials cultivation, production process control, finished products inspection and shipping are implemented in accordance with the strict standard operating procedures, to ensure stabile products according with the predetermined standard.

4. Monitor the drug circulation process, ensure the stability of the drugs quality from the drugs delivery to the use for patients, introduce the international pharmacovigilance (PV) idea, and collect, monitor, study and evaluate adverse reaction of drugs, to ensure the rational drug use of patients and doctors.

5. Adopt the advanced inspection instrument and equipment, reliable inspection method, and test the raw materials, packaging materials, intermediates, finished products, stability, samples, to provide strong support for quality assurance.

6. Quality is the root of enterprises, and the quality management system with international level will be built in the next five years, to provide an escort for achieving the company products globalization, the company internationalization.

Institution setting

Quality management department is responsible for the daily quality management work of the company.

1) The general manager is the lead of enterprises, the main responsible person of drug quality, and is fully responsible for daily management of enterprises;

2) The deputy general manager of the quality assists the general manager in quality management, responsible person of the company's quality management, authorized person of quality, fully responsible for product quality, responsible for implementing drug quality management laws and regulations, and organizing and standardizing the drug production quality management of the company, establishing and perfecting the company’s drug quality management system, and monitoring system, to ensure its effective operation;

3) The quality management department set in the company is responsible for the daily quality management, including quality assurance department (QA), quality control department (QC), to implement various quality management functions.

Quality assurance (QA) system

Taking the quality as the root, the whole process from the choice of starting materials suppliers to the product release, from the product development to clinical rational drug use, is managed and controlled in accordance with the strict quality standards and specification requirements, and quality assurance system is constantly improved, to ensure the product quality.

The production site and the whole process of its matched utility system are monitored and managed, to ensure product quality and regulatory compliance. Perfect the file, verify and change control system, standardize supplier management, establish customer complaint handling, adverse reaction report and monitoring mechanism, and manage the whole quality assurance system of the company through periodic self-inspection and other forms. And meanwhile carry out the quality risk management, deviation handling and CAPA, to ensure its effective operation, and to ensure the medication safety of patients.

Build the perfect quality assurance system of raw material pharmaceutical factory and plants pharmacy, control the quality of raw material and Chinese medicinal materials from the source, and ensure the stable and reliable raw materials and medicinal materials quality required by the preparation factory.

The opening meeting of the comprehensive self-inspection in 2016

Quality control system

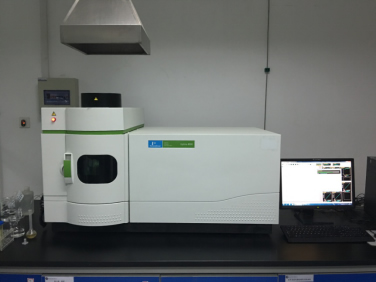

In order to guarantee the quality of products, establish high-standard quality control center, which is equipped with various advanced quality detection and analysis instrument, such as waters high performance liquid chromatograph, waters ultra high performance liquid chromatograph, PE gas chromatograph, PE inductively coupled plasma atomic emission spectrometer, UV2450 ultraviolet visible spectrophotometer, Hangzhou Tailin soft cabin H7Y-S22400B and RT-DTC hard cabin aseptic isolator, etc., satisfying different demands of drug quality inspection, and create QC lab with high technical level and the detection capability under GMP specification.

Quality control center has instruments group, physical and chemical group, bioassay group and standard group, and undertakes the whole process inspection of the raw materials, intermediates and finished products inspection of the preparation plant, raw material factory, as well as the sample detection, methodology transfer of the research and development pilot plant, trial production. The stability survey, daily environment monitoring in the clean area are also an important part of quality control center, to issue the inspection data accurately and timely for the requirements.

Quality control center

Quality lab

ICP

HPLC